how to measure metal thickness|base metal thickness chart : traders When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the webJugadores actuales de FC Miami City Champions. Ethan Sonis, Ronaldo Belgrove, Damir Zamora. La plantilla actual, las estadísticas y el rendimiento actual de los jugadores de FC Miami City Champions se pueden consultar en esta página. También dispones de estadísticas de cada jugador para todas las competiciones en las que se muestra el total .

{plog:ftitle_list}

webSmart Fit, São Paulo, Brazil. 31 likes · 2 talking about this · 328 were here. Gym/Physical Fitness Center

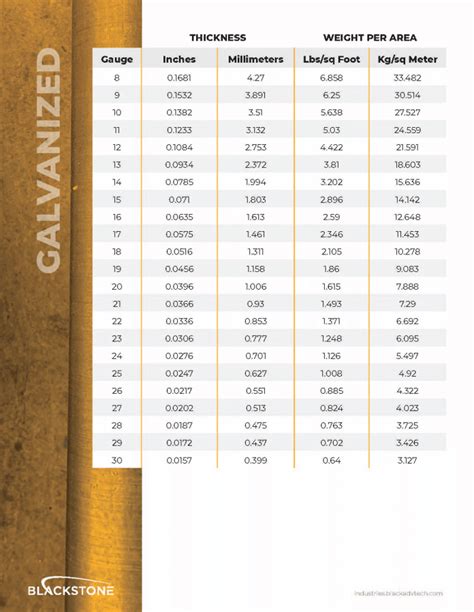

The chart below can be used to determine the equivalent sheet thickness, in inches .

правила работы с влагомером древесины

DeFelsko paint thickness gauges for magnetic grades of steel. PosiTest — Magnetic pull-off thickness gage (banana gauge) for the non-destructive measurement of non-magnetic coatings (paint, enamel, galvanizing, .Ultrasonic thickness gauging is a widely used nondestructive technique for measuring the thickness of a material from one side. Just about anything made out of metal, plastic, composite, ceramic, glass, fiberglass, or rubber can be measured. This tutorial provides a basic introduction to the theory and practice of ultrasonic thickness gauging .When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the

Sheet metal gauge is a fundamental measurement in metalworking that denotes the thickness of sheet metal. Originating from the Browne & Sharpe system in North America, gauge is a standardized unit used to specify the thickness of metal sheets, plates, and wire. It is a coincidence that the measuring device is roughly the size of the screw head in millimeters. A 6-gauge screw has a head that is almost 6 mm wide. The correlation between diameter (metric in mm), thickness (imperial) and head size is complicated. Nowhere can you find information that guarantees you can calculate this effectively. The sheet metal gauge system helps determine the thickness or diameter of different materials, such as metal and wire, based on their weight. Gauge is sometimes called “gage,” often denoted by a number followed by “ga.” The gauge chart system consists of a series of numbered gauges, with their specific thickness represented on a gauge .

What are sheet metal gauges? Gauges are used to measure the material thickness of a sheet of metal. These units are neither standard of metric and are completely independent of those typical measurement systems. Keeping a gauge conversion chart nearby is an easy way to determine the actual thickness of a sheet of metal in inches or millimeters.

STK: A measurement of starting raw material thickness. Contrary to belief, the expanding process does not directly alter material thickness. Strand Thickness should not be confused with the overall height or depth of expanded metal. Typically, mesh height can be as much as 1-2 times the measurement of SWDT. How to Measure a Flattened Mesh

As metal moves over the top of the roller, the laser calculates the height of the metal to be used as the thickness of the metal. A single laser can be used for one point of measurement or multiple sensors across the roll for multiple thickness measurement points.

A gauge is a traditional, non-linear measurement. The most commonly used sheet metal sizes range from 30 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness, and show both the gauge number as well as the thickness of the metal in thousandths of an inch.Similarly to Average thicknesses, it is at the plater’s discretion where to measure the product unless the measuring location is indicated on the print. If the range is ≤ 0.00015” (150uin) it is treated as a single average with the mid point of the range being the target average and the definition of average thickness above applies. Here are some common problems and ways to measure coating thickness. Advertisement The Voice of the Finishing Industry Since 1936 . In the metal finishing industry, the thickness of a coating can dictate the functionality, appearance and cost of a final product. Coating thicknesses are typically found in the range from 0.1 to 85+ microns .

Common applications for eddy-current coating thickness measurement include liquid or powder coating over aluminum and non-magnetic stainless steel as well as anodize over aluminum. Selecting A Gage. Many instruments available today combine both magnetic induction and eddy-current methods. Using a caliper: This instrument can measure both the thickness and width of expanded metal, making it a versatile tool for measuring expanded metal sheets. To use a caliper, place the sheet onto a flat surface and open the jaws to fit inside the expanded metal’s openings, ensuring that the jaws are perpendicular to the sheet’s surface.

GAUGE TO THICKNESS CHART Gauge Stainless Galvanized Sheet Steel Aluminum Fraction inches (mm) inches (mm) inches (mm) inches (mm) 30 0.0125 (0.33) 0.0157 (0.40) 0.0120 (0.30) 0.0100 (0.25) 29 0.0141 (0.36) 0.0172 (0.44) 0.0135 (0.34) 0.0113 (0.29) 28 1/64 0.0156 (0.41) 0.0187 (0.47) 0.0149 (0.38) 0.0126 (0.32) Measure the width of a thread in fractions of an inch to get the diameter. Use a ruler or measuring tape to measure from one side of a thread to the other using the nearest fraction of an inch. This diameter for screws in the . Measure the thickness of the entire stack with a ruler. Set a ruler against the edge of the stack. Press it down firmly against the table. . on one end. If you’re using a digital model, it will also have a display situated on the .Learn how to measure stamped sheet metal thickness with MTI’s Digital Accumeasure, a high-precision capacitance measurement system with nanometer accuracy and stability.. Problem. High silicon steels are alloys of iron and silicon that are easily magnetized and demagnetized. They can be supplied as sheet metal with a very thin dielectric coating.

Step 2: Measure Expanded Metal Thickness. Using a caliper, measure the thickness of the expanded metal sheet or panel. This will help you determine the gauge or wire diameter of the material. Expanded metal is defined by its mesh size, which refers to the distance between two adjacent strands. Measure the mesh size using a ruler or tape measure.

A variety of electronic instruments are available for measuring after cure powder coating thickness on metal parts. They use a magnetic principle when measuring on steel and an eddy-current principle on aluminum. . The normal standard used in powder thickness measurement is the mil, where 1 mil is equal to a thousandth of an inch (1/1000 .

sheet metal size chart

Metal gauge thickness (aka gage thickness) dates back to the 1800s, before a unit of measure for thickness was universally agreed upon. It is a way of measuring the thickness of material via density. The processes of manufacturing at the time when the gauge system was developed were crude by today’s standards, so material thickness was very .The starting raw metal thickness will determine how thick or thin strands can be. The expanded metal tool, typically called a knife, will determine how large the openings are able to be. Lastly, larger openings will create more airflow. All these variations need to be considered in conjunction with your specific project. Once this is determined .This average value is called the “base metal reading” or “BMR”. Measure the zinc thickness at the number of spots required by the relevant procedure or standard. Subtract the base metal reading (BMR) from the gage reading to obtain the galvanizing thickness. When utilizing an electronic coating thickness gauge, perform the following steps:

How to Quickly Measure Sheet Metal’s Thickness. When it comes to measuring sheet metal thickness, there are several methods at your disposal. However, some techniques are more accurate and reliable than others. Option 1: Using Calipers. Calipers are an accurate measuring tool used to measure the thickness of a sheet of metal. Gauge is a measurement of the thickness of a metal roofing panel. There are a variety of roofing panels that can be used to cover roofs. Manufacturers in the United States use gauge to express the thickness of metal roof panels. Roof panels vary in thickness from 22 gauge to 29 gauge. The smaller the number, the thicker the panel. There are also gauge numbers like 000000 and 0 for aluminum and stainless steel, the metal thickness of 000000 gauge is larger than 0 gauge. How Does Sheet Metal Gauge Work? . the numbers are independent of measurement systems and do not mean actually measured value. In addition, the same gauge number for different materials presents . gauge non-ferrous metal alum, brass, etc. inches galvanized steel inches standard steel inches stainless steel inches; 1.2893.2812: 2.2576.2656: 3.2294.2391.2500

sheet gauge to mm chart

Resultado da 25 de ago. de 2023 · An exclusive application for those who like football, it is the time for sports in real time.

how to measure metal thickness|base metal thickness chart